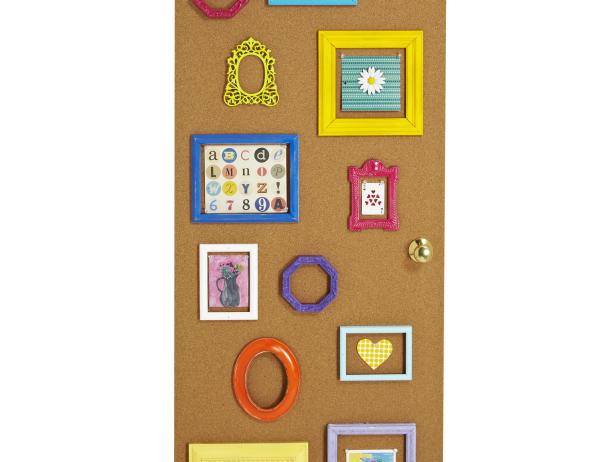

4 Ways to Decorate a Door for a Kid's Room

In the first ever HGTV Magazine for Kids, the DIY experts created door designs that work with kids’ fun personalities. Find what works best for your child and create one together.

13 Great Front Door and Plant Color Combos

These eye-catching entryways are charming, cheerful and even a bit quirky.

20+ Front Door Looks We're Obsessed With

Come on in! HGTV Magazine has all the front porch inspo you need.

Home Gym Pictures From HGTV Dream Home 2017 16 Photos

Check out this sliding barn door plus all the other stylish details of HGTV's Dream Home 2017.