Homesteading

Learn more about this self-sufficient lifestyle with our tips on beekeeping and tending chickens, ducks and goats in your own backyard.

Maybe you or someone you know keeps chickens. But what about raising ducks? Duck eggs are tasty, ducks are social creatures, and ducklings are as cute as can be.

The only thing cuter than a baby animal? Baby animals with their mothers.

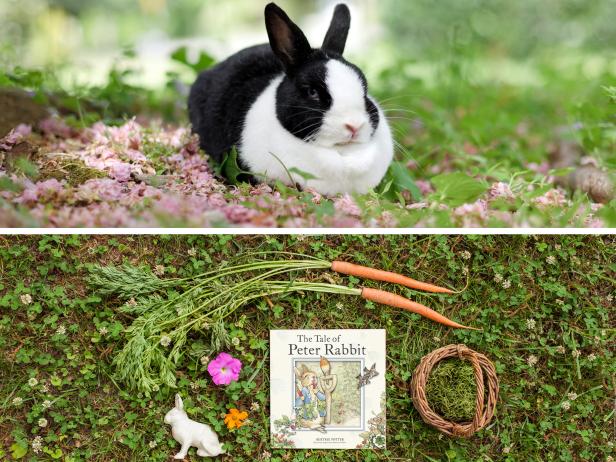

Discover what your favorite critters are eating, reading and pilfering from your yard in these pictures of fauna at play.

Go Shopping

Get product recommendations from HGTV editors, plus can’t-miss sales and deals.